Understanding Tevo Tarantula Nozzle Leaks

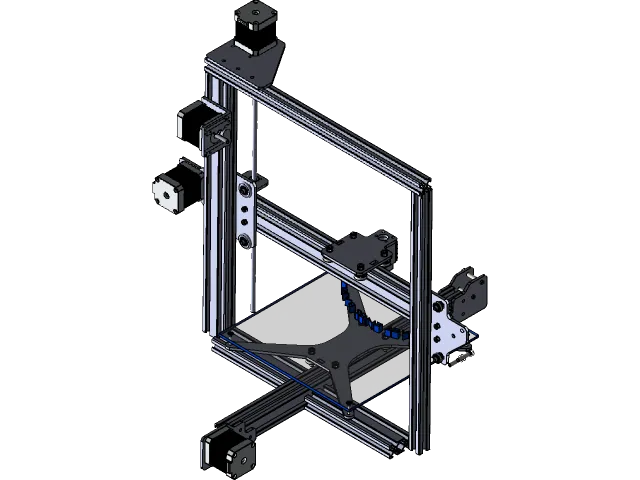

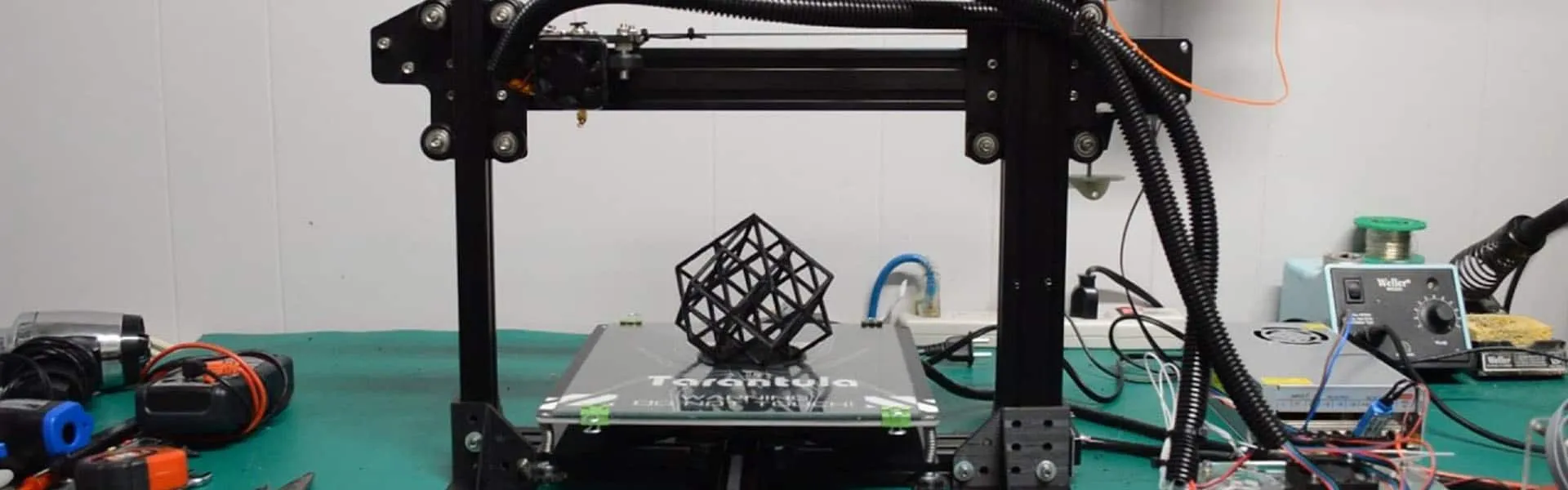

A Tevo Tarantula nozzle leak is a frustrating issue for any 3D printing enthusiast. It leads to messy prints, wasted filament, and potential damage to your printer. Understanding the causes of these leaks is the first step in preventing and solving them. This article will explore the top 5 reasons behind nozzle leaks in the Tevo Tarantula, providing insights and solutions to get you back to printing smoothly. Proper maintenance and understanding the inner workings of your 3D printer are crucial for optimal performance. This knowledge helps you troubleshoot problems and ensures consistent, high-quality prints. The Tevo Tarantula, like any 3D printer, can experience various issues, but nozzle leaks are among the most common and disruptive.

Common Causes of Nozzle Leaks

Improper Nozzle Installation

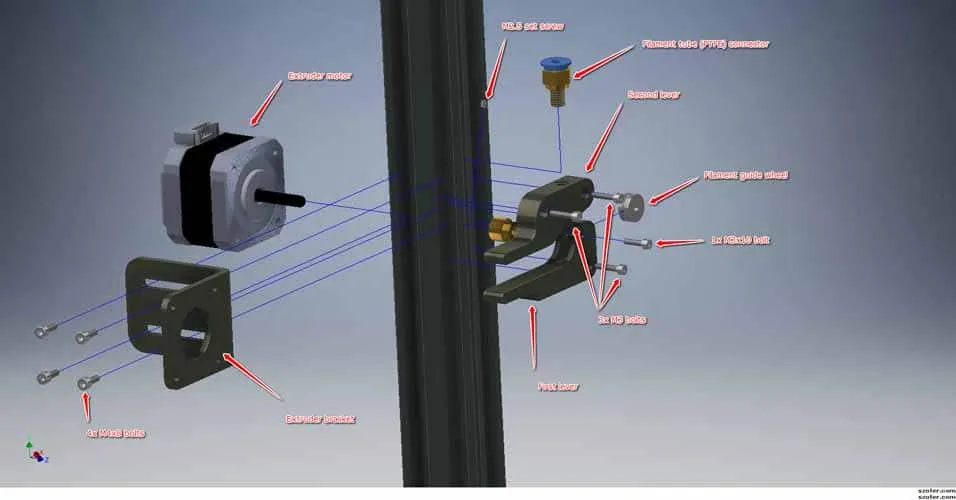

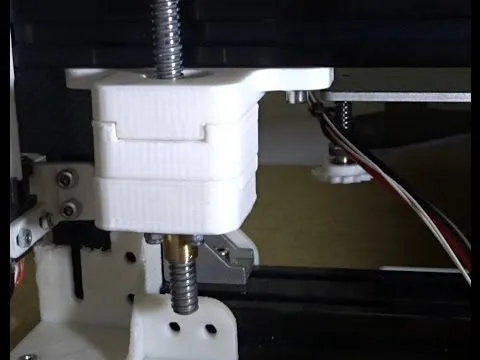

One of the most frequent culprits behind nozzle leaks is improper installation. This can encompass several mistakes made during the nozzle replacement or initial setup process. Incorrect installation often leads to gaps that filament can seep through. Ensure the nozzle is tightened correctly against the heat break to form a tight seal, preventing molten plastic from escaping. Using the correct tools and following the manufacturer’s instructions can mitigate this problem effectively. Always make sure to heat the hot end before tightening or removing the nozzle to prevent damage to the threads. Proper installation is a foundational step in achieving reliable 3D prints. The image tevo-tarantula-nozzle-leak-overview.webp can provide a visual guide.

Incorrect Tightening Torque

Applying the wrong amount of torque when tightening the nozzle is a common error. Overtightening can damage the nozzle or the heat block threads, while undertightening will leave gaps that lead to leaks. The nozzle needs to be snug but not forced. Consult the manufacturer’s specifications for the recommended torque. Using the right tools, such as a wrench with the correct size and shape, and a torque wrench, can help ensure the right amount of force is applied. It is important to strike a balance between a secure seal and avoiding damage. This ensures a proper seal to prevent filament from leaking during the 3D printing process. Proper torque is essential for both the structural integrity of the nozzle assembly and leak prevention.

Cold Tightening

Tightening the nozzle while the hot end is cold is a frequent mistake. This can lead to an imperfect seal because the metal expands when heated. The expansion and contraction of the metals in the nozzle and heat block affect how tightly they fit together. Always tighten the nozzle when the hot end is at its operating temperature. This will ensure a tight seal when printing. Heating the hot end will allow the parts to expand and conform to each other, creating a better seal. Furthermore, cold tightening can strip the threads, so applying heat is critical to prevent this damage. This is why it is often recommended to heat the hot end to the printing temperature before securing the nozzle.

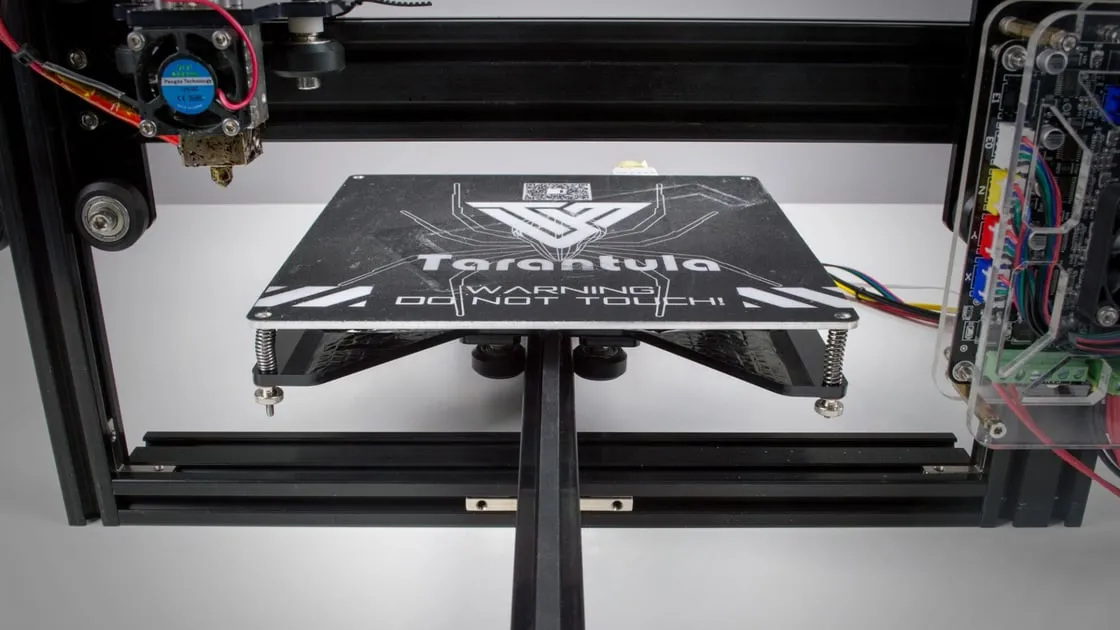

Nozzle Not Seated Correctly

If the nozzle isn’t properly seated against the heat break, there will be a gap. Even a tiny gap is enough for the molten plastic to seep out. Carefully align the nozzle and ensure it sits flush with the heat break. Any misalignment compromises the seal and can lead to leaks. Check that the nozzle’s threads are clean and free from any debris before installation. A thorough inspection and proper alignment are crucial steps in preventing leaks. The image improper-nozzle-installation.webp shows how the nozzle should be seated correctly.

Overheating

Overheating can cause filament to melt and leak from the nozzle. When the hot end operates at excessively high temperatures, it can cause the filament to degrade, leading to a leak. Always monitor and control the printing temperature within the recommended range for the specific filament type. Adjust the temperature settings in your slicing software or on your printer’s control panel. Overheating can also contribute to other issues, such as clogging, making it essential to maintain proper temperature settings. The image overheating-3d-printer.webp illustrates the issues arising from excessively high temperatures.

High Temperatures

Operating the hot end at high temperatures can cause the plastic to become too fluid and prone to leakage. Exceeding the filament’s recommended temperature range often results in melted plastic seeping out of the nozzle. Always refer to the filament manufacturer’s guidelines for the optimal printing temperature. Adjust the temperature settings in small increments until you achieve the best results. Experimenting with different temperatures helps to find the sweet spot where the filament flows smoothly without leaking. Consistent monitoring and adjustment are crucial to preventing leaks due to high temperatures.

Heat Creep

Heat creep occurs when heat travels up the heat break, causing the filament to soften prematurely above the nozzle. This can result in a clog or leak. Ensure that the cooling system, such as a fan, is functioning correctly. Properly cooling the heat break and the filament can prevent heat creep. Additionally, make sure the heat break is adequately insulated. If you’re experiencing frequent clogs or leaks, check the cooling system and consider upgrading it if necessary. A well-functioning cooling system is vital for preventing heat creep. The image overheating-3d-printer.webp highlights this issue.

Damaged Components

Damaged or worn components within the hot end assembly can also lead to leaks. Inspect the nozzle, heat break, and heat block for any signs of damage. Regular inspection and replacement of worn parts are critical for maintaining print quality and preventing leaks. Using high-quality replacement parts will help ensure proper sealing and performance. Pay close attention to the condition of the threads on the nozzle and heat break. This helps in ensuring that the nozzle screws in properly, forming a tight seal. Check the image damaged-nozzle-component.webp for signs of component failure.

Worn Nozzle Threads

Worn nozzle threads can prevent a proper seal, leading to leaks. As the nozzle is repeatedly tightened and loosened, the threads can wear down. Inspect the threads regularly for any signs of damage or wear. If the threads are damaged, replace the nozzle immediately. Using high-quality nozzles and carefully tightening them can help extend their lifespan. Proper maintenance ensures that the threads remain intact and the nozzle seals correctly. A worn nozzle can compromise the structural integrity of the hot end.

Damaged Heat Break

A damaged heat break can create a gap that allows molten plastic to escape. The heat break is the component that separates the hot and cold zones of the hot end. Inspect the heat break for cracks or damage. If any damage is found, replace the heat break immediately. The heat break is crucial in preventing heat creep, so ensure it’s in good condition. Regularly checking the heat break can help prevent leaks and clogs. Ensure the heat break is correctly installed and securely mounted to maintain a proper seal. This component is essential for preventing nozzle leaks.

Incorrect Printing Settings

Inaccurate printing settings, such as excessive retraction or incorrect temperatures, can also cause nozzle leaks. Review the settings in your slicing software to ensure they’re optimized for the filament type and the printer. Incorrect settings can lead to various printing problems, including leaks. Experimenting with different settings can help you find the optimal configuration for your prints. Careful calibration and adjustments are essential for preventing leaks. Monitoring your settings and adjusting them as needed is a key part of the 3D printing process. The image incorrect-printing-settings.webp illustrates this problem.

Excessive Retraction Settings

Excessive retraction settings can pull the molten filament back into the hot end, causing a vacuum. When the nozzle moves to a different location, this can cause the filament to ooze out. Optimize the retraction settings in your slicer to prevent this issue. Experiment with different retraction distances and speeds to find the best settings for your filament and printer. Too much retraction can lead to clogs and oozing. Retraction settings must be finely tuned to prevent both stringing and leaks. It is important to balance the retraction settings to ensure clean prints.

Printing Too Hot

Printing at temperatures higher than the filament’s recommended range increases the risk of leaks. This can cause the filament to become too fluid. Always verify the recommended printing temperature for the specific filament you are using. Reducing the printing temperature can often resolve nozzle leaks. Adjust the temperature in small increments to achieve optimal print quality. Printing too hot can lead to various printing issues, including stringing and blobs. Monitoring the temperature is important for consistent, high-quality prints.

Low Quality Filament

The quality of the filament plays a significant role in preventing nozzle leaks. Using low-quality filament can lead to inconsistent melting and oozing. Always opt for reliable filament brands that maintain consistent quality. Good-quality filament ensures that your printer operates at its best. Consider testing different filaments to see which ones perform best on your Tevo Tarantula. Using reliable filament is an essential aspect of successful 3D printing.

Filament Degradation

Filament can degrade over time, especially if it’s exposed to moisture or heat. This degradation can alter the filament’s properties and increase the likelihood of leaks. Store your filament in a dry, airtight container when not in use. Regularly inspect the filament for signs of degradation, such as brittleness or discoloration. Degradation causes inconsistencies in the filament and printing. If the filament is degraded, replace it with a new spool. Proper storage is crucial for extending the lifespan of your filament. Regularly check the condition of the filament spool.

Contaminated Filament

Contaminated filament can lead to nozzle leaks and other printing problems. Dust, debris, or other particles in the filament can disrupt the flow and cause leaks. Protect the filament from contamination during storage and use. Ensure that the filament path is clean and free from obstructions. Run a filament cleaner before each print if needed. If you suspect that the filament is contaminated, consider using a new spool or cleaning the current one. The quality and purity of the filament are important for successful prints.

Troubleshooting and Solutions

Inspecting and Replacing Components

Regularly inspect your nozzle and heat block for any damage or wear. If you find any issues, replace the affected components. This proactive approach can prevent leaks and improve your print quality. Keep spare parts on hand so you can replace components immediately. The image troubleshooting-nozzle-leak.webp provides a reference.

Tightening the Nozzle Correctly

Always heat the hot end before tightening or loosening the nozzle. Use the correct torque and tools. Properly tightening the nozzle is critical to prevent leaks. Avoid over-tightening the nozzle as this can damage the threads. Applying the right amount of force helps create a proper seal. Follow the manufacturer’s instructions for the correct torque values. This process is essential for a successful print.

Optimizing Printing Parameters

Experiment with the printing settings in your slicer to find the optimal settings for the filament you are using. Adjust the temperature, retraction, and other parameters as needed. This involves trial and error, but it’s essential for eliminating leaks. Use the recommendations provided by the filament manufacturer as a starting point. Fine-tune the settings until you get the best results. Adjust settings in small increments. Using the correct printing parameters helps you prevent leaks.

Preventing Nozzle Leaks

Preventing nozzle leaks in your Tevo Tarantula involves a combination of proper maintenance, understanding the causes, and making the necessary adjustments. Regular maintenance, such as checking the nozzle and ensuring proper installation, will help prevent leaks. Monitor and adjust your printing settings to match the filament and the environment. By addressing these issues, you can significantly reduce the chance of nozzle leaks and enjoy successful 3D printing. Consistent monitoring and preventative measures are the keys to avoiding this issue. These practices will lead to more consistent and reliable prints.