Understanding Tevo Tarantula Screws

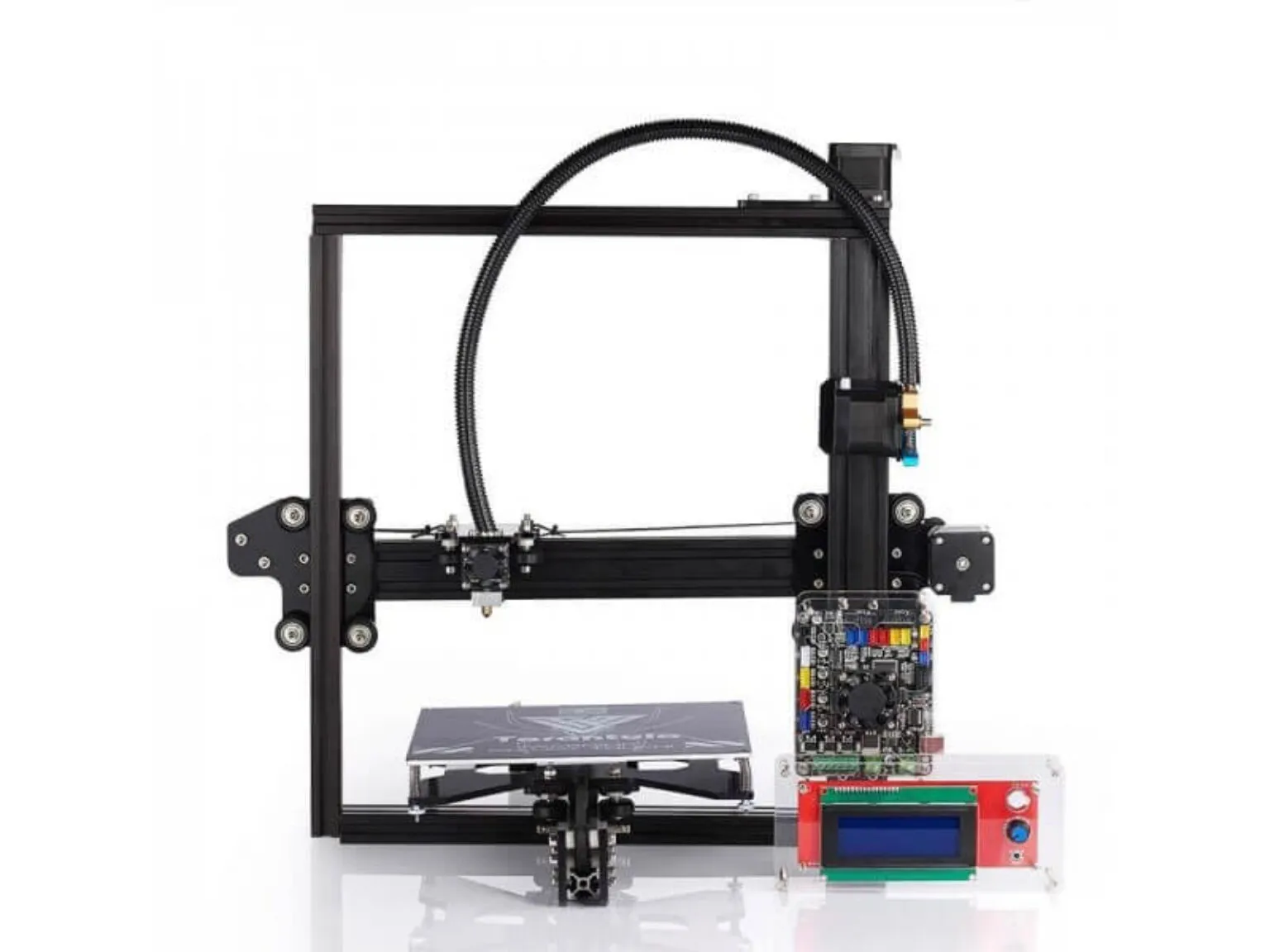

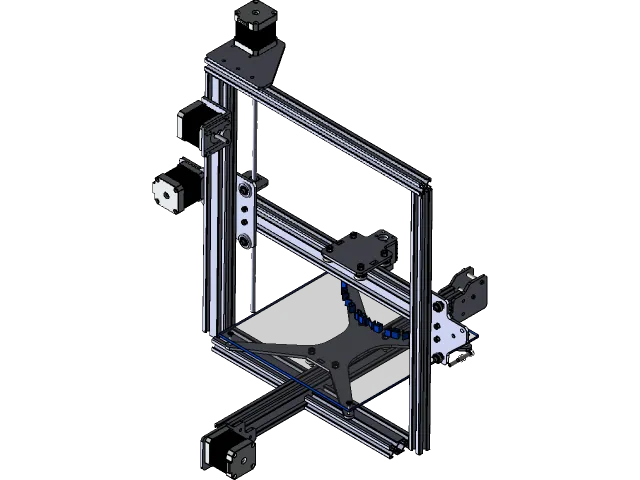

The Tevo Tarantula 3D printer, like any piece of mechanical equipment, relies heavily on screws for its structural integrity and functionality. These seemingly small components are crucial for holding the printer’s frame, moving parts, and electronic components together. Over time, screws can loosen, strip, corrode, or otherwise fail, leading to printing inaccuracies, mechanical issues, and even complete printer failure. Understanding the role of these screws and how to address their problems is vital for all Tevo Tarantula owners to ensure their printer operates smoothly and efficiently. Proper screw maintenance and replacement are essential aspects of printer upkeep and can prevent many common issues.

Common Screw Problems in Tevo Tarantula

Several issues can plague the screws on your Tevo Tarantula. Recognizing these problems early on can save you significant time and frustration. These issues typically arise from vibrations during printing, the repeated heating and cooling cycles experienced by the printer, and the stress placed on the screws during printer operation. Regularly inspecting your printer for these issues is crucial to maintaining peak performance and print quality. Understanding the cause of each issue allows you to take appropriate preventative measures.

Loose Screws

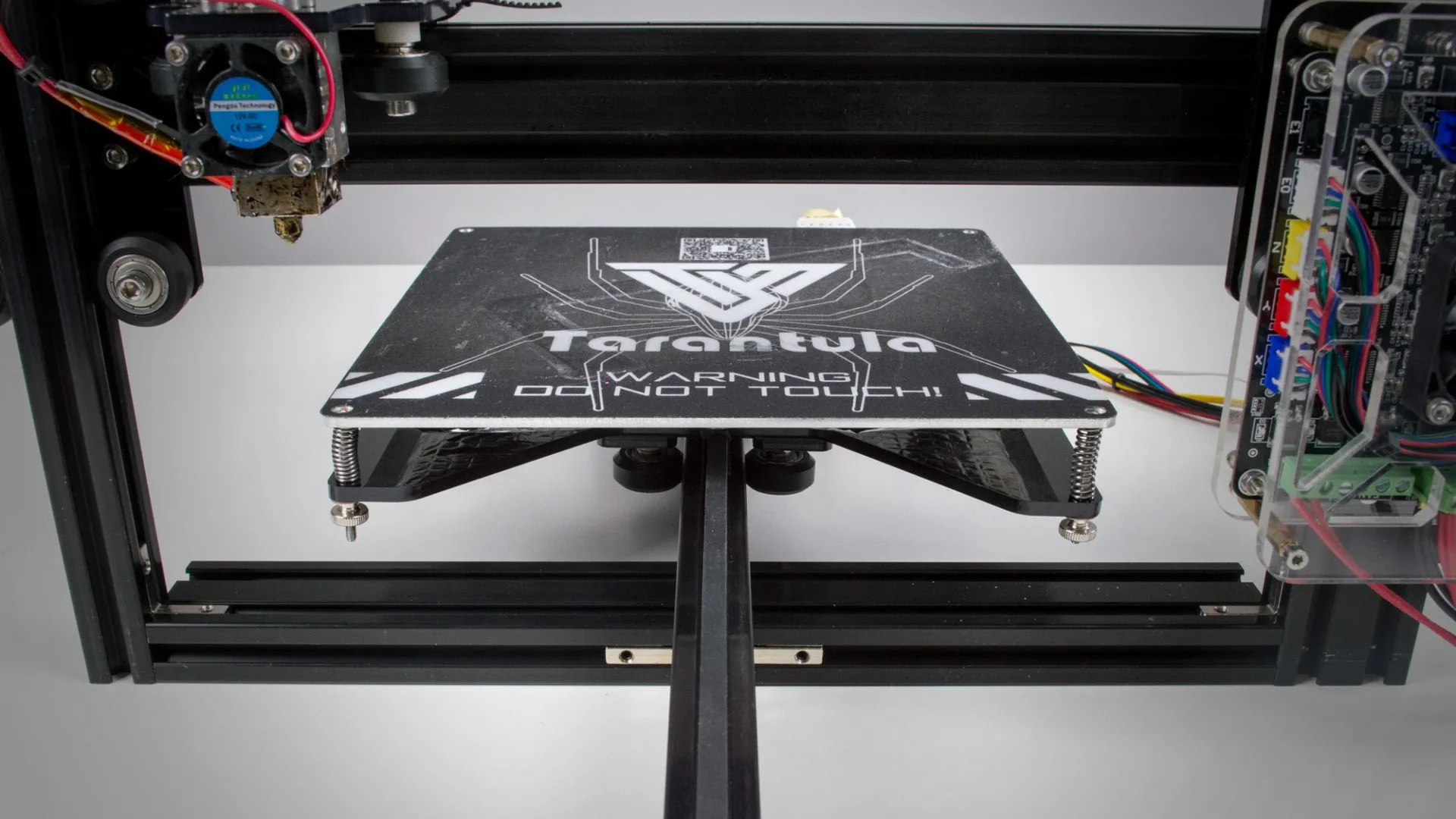

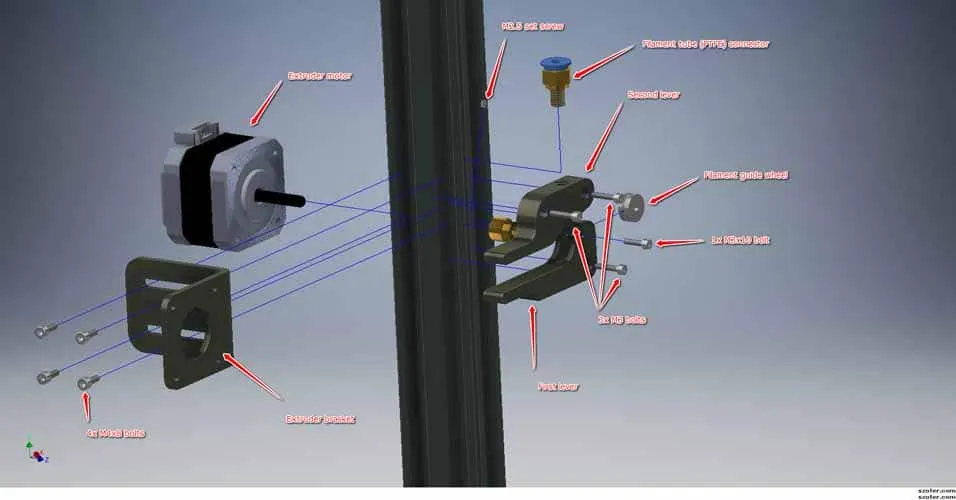

Loose screws are perhaps the most common issue. Vibrations from the printer’s motors and moving parts gradually cause screws to work themselves loose. This can lead to misaligned components, wobbling, and ultimately, poor print quality. Regularly check the screws on your printer, especially those on the frame, bed, and extruder assembly. Tightening loose screws is usually a simple fix, but neglecting them can lead to more serious problems.

Stripped Screws

Stripped screws occur when the threads in the screw or the receiving hole are damaged. This can happen from over-tightening, using the wrong size screwdriver, or from the screw being repeatedly removed and re-inserted. Stripped screws no longer grip, leading to loose components. Replacing a stripped screw often involves using a slightly larger screw, using a screw with a different thread type, or repairing the screw hole with specialized tools or materials.

Corroded Screws

Corrosion can occur due to humidity, exposure to chemicals, or the type of material the screws are made of. Corroded screws can become difficult to remove and may fail under stress. Replacing corroded screws with stainless steel or other corrosion-resistant materials is a good practice to prevent future issues. Inspect your printer regularly, especially if it is used in an environment with fluctuating humidity levels or exposure to chemicals.

Tools and Materials You’ll Need

Having the right tools and materials on hand is critical for successfully replacing screws on your Tevo Tarantula. Being prepared can make the process much smoother and more efficient. Assemble these items before you start the replacement process. It’s also good to have a well-lit workspace to ensure you can see the screws clearly.

Screwdriver Set

A good quality screwdriver set is essential. The Tevo Tarantula uses a variety of screw types, including Phillips head and possibly some hex or Allen head screws. Choose a set that includes a range of sizes to accommodate all screws on your printer. Using the correct size screwdriver is crucial to prevent stripping the screw heads.

Replacement Screws

Keep a supply of replacement screws. You can purchase a screw kit specifically for 3D printers or a general assortment of screws. Ensure the screws are the correct size and thread type for your printer. Having replacement screws readily available will save you time and prevent you from having to stop printing while you search for the correct parts.

Allen Wrench Set

If your Tevo Tarantula uses hex or Allen head screws, an Allen wrench set is a must. These wrenches are typically L-shaped and come in various sizes. Make sure you have a set that includes the sizes used on your printer. Using the correct size Allen wrench is essential to avoid stripping the screw heads.

Step-by-Step Guide to Replacing Screws

Following a systematic approach when replacing screws ensures the job is done correctly and minimizes the risk of further damage. Take your time, work in a well-lit area, and double-check your work as you go. It is also good to have the printer manual handy to reference screw locations and sizes if needed.

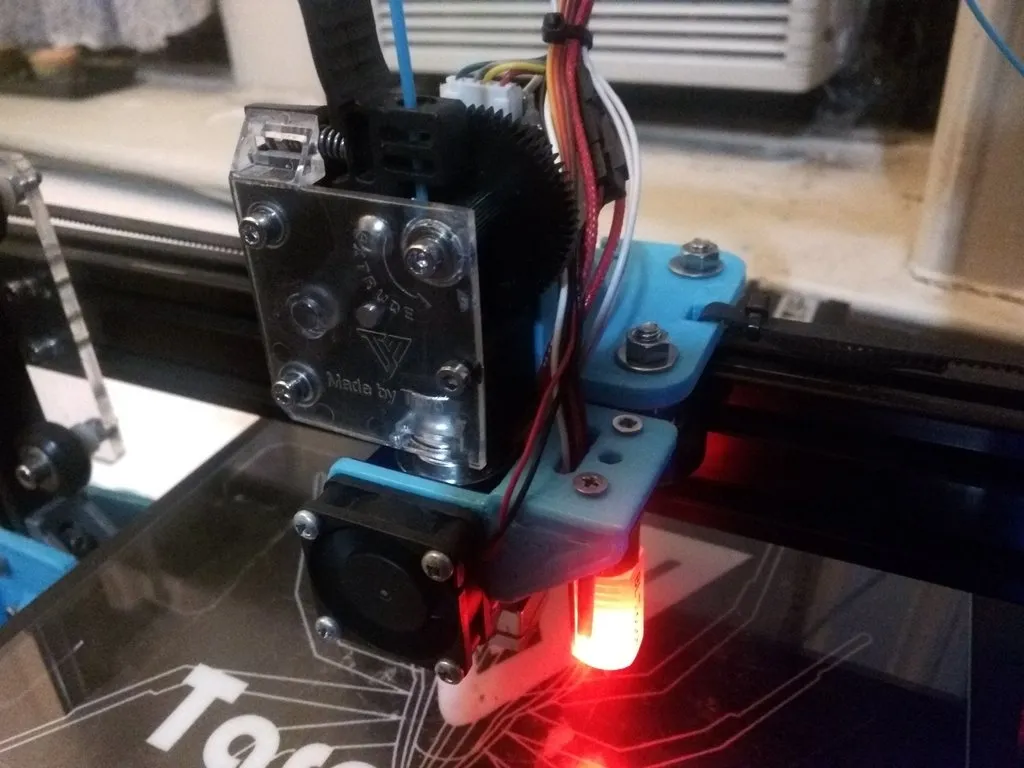

Identifying the Problem Screw

Before you start, identify the screw that needs replacing. Check for looseness, stripped threads, or corrosion. Examine the surrounding components to determine if the screw’s failure has caused any other issues. Note the screw’s location and any specific details, such as its size and type, to ensure you have a matching replacement.

Removing the Old Screw

Carefully remove the old screw using the appropriate screwdriver or Allen wrench. Apply gentle but firm pressure and turn the tool slowly. If the screw is difficult to remove, try applying penetrating oil or using a screw extractor tool. Avoid stripping the head of the screw during removal. If the screw head is stripped, you may need to use a screw extractor.

Installing the New Screw

Once the old screw is removed, insert the new screw into the hole. Align the screw and turn it clockwise by hand to ensure it is threading correctly. Once it is seated, tighten the screw using the appropriate tool. Do not over-tighten. Over-tightening can strip the screw or damage the receiving hole.

Tightening the Screw Properly

Tighten the screw until it is snug, but not overly tight. Over-tightening can strip the screw or damage the parts being held together. The appropriate level of tightness varies depending on the screw type and the materials. If you’re unsure, err on the side of caution and tighten the screw slightly less than you think is necessary, then recheck and adjust accordingly.

Troubleshooting Common Replacement Issues

Even with the best intentions, you might encounter some issues during the screw replacement process. Here are solutions to some common problems.

Screw Won’t Tighten

If the screw won’t tighten, the threads may be stripped or the screw could be cross-threaded. Remove the screw and inspect both the screw and the hole. If the threads are damaged, you may need to use a larger screw or a screw with a different thread type. If the screw is cross-threaded, carefully realign the screw and try again, or consider using a thread tap to re-cut the threads.

Screw Head Stripped During Removal

If the screw head strips during removal, you can try several methods. First, try using a screw extractor. If that doesn’t work, you can try using a rubber band or steel wool between the screwdriver and the screw head to increase grip. You may also need to drill out the screw head or use pliers to grip the remaining screw. Be careful not to damage surrounding components.

Screw Hole is Damaged

If the screw hole is damaged, you may need to repair it. One option is to use a thread repair insert. These inserts are designed to provide new threads in a damaged hole. Another option is to fill the hole with epoxy or a similar material and re-drill it. Consider using a larger screw or moving the screw’s position slightly if possible.

Preventative Maintenance and Tips

Regular maintenance can significantly extend the life of your Tevo Tarantula and prevent screw-related issues. Implementing these preventative measures can save you time and trouble.

Regular Inspection

Regularly inspect all screws on your Tevo Tarantula for looseness, corrosion, or damage. Check the frame, bed, extruder, and any other moving parts. Schedule this inspection as part of your regular maintenance routine. Catching issues early prevents them from escalating into more serious problems.

Proper Tightening Techniques

When tightening screws, avoid over-tightening. Overtightening can strip the screw heads or damage the components. Use the appropriate tool size and apply a moderate amount of force. If you are unsure, tighten the screw slightly and recheck for looseness later. Periodic checks can ensure screws remain secure without damage.

Using Thread Locker

Consider using thread locker on screws that are prone to loosening due to vibrations. Thread locker comes in various strengths and is designed to prevent screws from coming loose. Apply a small amount of thread locker to the screw threads before installing them. Use the appropriate type of thread locker based on the screw material and the printer’s environment. Be aware that thread locker can make screws more difficult to remove if you need to service them later.